Air-water cooling system is widely used in for solid state HF welder and other various induction heating equipment.

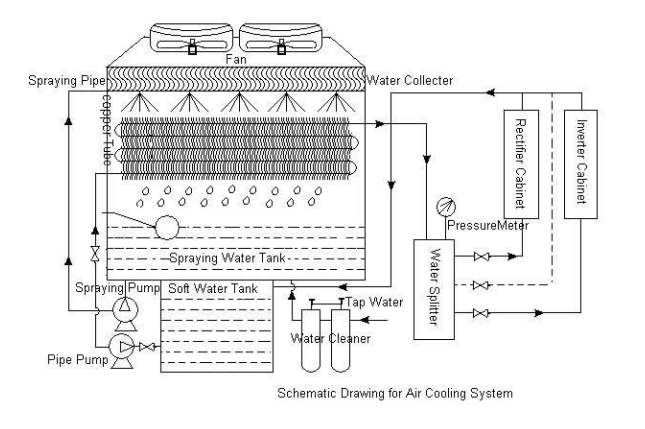

It adopts closed cooling tower structure. Cooling soft water flow in sealed water tank and cooling pipes.The inner circulation soft water is cooled by overhead fan and water-spray method using the principle of absorbing heat when evaporation.The spray water store at the bottom of cooling tower. soft water circulate inside the closed cooling tower's heat dissipation pipe. spray-water spray at pipes's surface by spray-water distribution system and sprayer through spray system. some heat is taken by dissipation and temperature of soft water inside the pipe goes down accordingly. The water in hot air and undissipated water flow through PVC heat exchange layer to cool the the water in the layer by the air. The temperature of the water goes down, meanwhile it flows to bottom of the cooling tower.

At Baoding Chaochang Electromechanical Co., Ltd., we take pride in being at the forefront of cutting-edge technology in the field of induction heating equipment. As a distinguished manufacturer, we are excited to present our latest innovation: the Air-Water Chiller, a pinnacle of efficiency and performance designed to meet the unique demands of modern industrial applications.

| Model | Cooling capacity(KW) | Heat-exchanging area | Dimension (mm) | ||

| L | W | H | |||

| FST-60 | 20 KW | 3 m2 | 2000 | 1100 | 1800 |

| FST-100 | 30 KW | 4 m2 | 2000 | 1100 | 2000 |

| FST-150 | 45 KW | 5 m2 | 2000 | 1100 | 2000 |

| FST-200 | 62 KW | 6 m2 | 2300 | 1160 | 2000 |

| FST-250 | 78 KW | 8 m2 | 2300 | 1160 | 2000 |

| FST-300 | 95 KW | 10 m2 | 2360 | 1160 | 2200 |

| FST-400 | 125 KW | 12 m2 | 2900 | 1160 | 2200 |

| FST-500 | 156 KW | 15 m2 | 2900 | 1250 | 2200 |

| FST-600 | 185 KW | 18 m2 | 3000 | 1250 | 2200 |

| FST-800 | 256 KW | 23 m2 | 3000 | 1800 | 2200 |

| FST-1000 | 313 KW | 31 m2 | 3000 | 1800 | 2400 |

| FST-2000 | 623 KW | 62 m2 | 3500 | 2000 | 2400 |

| FST-2500 | 800 KW | 80 m2 | 3500 | 2000 | 2500 |

| FST-3000 | 1000 KW | 100 m2 | 3500 | 2000 | 3000 |

| FST-4000 | 1300 KW | 120 m2 | 4000 | 2100 | 3300 |

| FST-5000 | 1500 KW | 150 m2 | 4500 | 2300 | 3400 |

| FST-6000 | 2000 KW | 180 m2 | 4500 | 4000 | 3500 |

1. 60 KW ~1200 KW induction welding machine, induction hardening machine, H.F. induction heating power supply, M.F. and super audio induction heating power supply, induction heating complete machines, rectifying machines,diathermanous machines, melting resistance welding machines, die casting machine and injection molding machine.

2. Quenching machine tool cooling

3. Other equipment needed cooling

4. According to consumer's request, various nonstandard products can be designed.

1. Energy saving: Low investment, small volume, compact frame, convenient installation, easy transfer and without any investment on building cooling pool and cooling tower.

2. Water saving: Water saving 95% compared with directly water supply cooler.

3. Electricity saving: Electricity saving above 90% compared with compressor cooling mode.

4. System adopts sealed soft water circulation, no scale, no jam.

5. High quality brass pipe of inner heat radiation condenser, high heat dissipation efficiency

6. Best cooling effect due to wind cooling and spray water complex cooling

mode which guarantee some key parts won’t damage due to over high

water temperature in summer such as SCR, capacitor, reactor, induction coil etc. Therefore prolong using life span of equipment

Hot liquid flows into tray pipe from bottom and flows out from top of tray pipe,spray pump send cooling water to spray pipe of the top of tray pipe, the cooling water is sprayed on the surface of tray pipe symmetrically, heat form tray pipe is absorbed by water, sprayed form top, part of them are evaporated into water vapor, air passes through tray pipe fin board by fan makes the surface of tray pipe dissipate compulsively, and bring water vapor into the air,some of them flow with the wind. To reduce water loss, water collector is installed at the top of spray pipe which collects water back into spray water box.

(Please refer to working principle for details)

The power supply device, load inductor and bus bus are cooled by water, and the condition of the cooling water provided directly affects the reliability of the equipment operation. It is suggested that the cooling water should be analyzed and tested, and the results should meet the following conditions. If there is any difference, it should be solved by relevant purification means. The heating power supply internal waterway main pipes and valves are made of stainless steel pipe, the cooling system is provided by the buyer, and the quality of cooling water should meet the following requirements:

1.Mechanical properties:

Transparent, non-turbid, no sediment (sieve size 0.38mm), total solid content does not exceed 250mgL.

2.Chemical properties:

The pH value PH should be in the range of 6 to 8.

Chloride ≤100mg/L.

Nitrite (NO2) ≤ 0.04mg/L.

Element Fe ≤ 0.3mg/L.

Element Mn ≤ 0.05mg/L.

Element S≤more than 250mg/L.

3.Conductivity: not more than 600 μ s / cm.

4.Influent temperature: not less than 5 ℃, not higher than 30 ℃. When supplying water in hot days, the surface condensation of water cooling elements must be avoided.

5.Inlet pressure: 0.18~0.25 MPa (about 1.8~2.5kg/cm2).

At Baoding Chaochang Electromechanical Co., Ltd., we believe in pushing the boundaries of technology to empower industries with solutions that enhance productivity, reduce environmental impact, and drive innovation. Our Air-Water Chiller stands as a testament to our dedication to excellence, providing a cooling solution that exceeds expectations and outperforms the competition.

Experience the future of cooling technology with us. Contact us today to learn more about how our Air-Water Chiller can revolutionize your industrial processes.

Baoding Chaochang Electromechanical Co., Ltd.

Copyright © Baoding Chaochang Electromechanical Co., Ltd. All Rights Reserved | Sitemap