Induction annealing is a heat treatment process involving the heating of a material above its recrystallization temperature. The main purpose of annealing is to bring the internal organization of the metal to or near equilibrium in preparation for subsequent processing and final heat treatment. Since annealing treatment changes the physical and chemical properties of the material, some materials, such as steel, require slow cooling before annealing can be performed. Copper and silver, on the other hand, have the option of hardening treatments.

We supply induction annealing equipment that is well suited for induction annealing. Induction annealing machines are specifically designed to anneal austenitic stainless steels and copper. In addition to induction heat treating, bonding or annealing, these induction annealers are ideal for welding, brazing, curing and hardening large parts, including ferrous and non-ferrous alloys. The complete set of equipment is composed of medium frequency heating power supply, water cable, tank capacitor cabinet, inductor, water cooling system, lifting and swinging Angle mechanism, welding seam detector, temperature measuring instrument, operating console and so on.

Heating Temperature: From Indoor Temperature ~ Craft Annealing Temperature

The Device consist of: SCR M.F.heating power, On-line Annealing inductor / Inductor lifting bracket and operation console

Single-machine Power: 100 ~ 1000 KW, Multiple devices can be connected

Rated Power: 400 ~ 8000 HZ

Application Scope: Petroleum Pipeline, High-Pressure Fluid Tube and other top quality pipes

On-line Annealing inductor / Inductor lifting bracket: consist of inductor with magnetic material、mechanical adjustable bracket、capacitor cabinet etc.

The heating power cabinet was controlled by operation console 、The inductor would avoid burrs of pipe/ tube、seam annealing temperature was closed loop controlled.

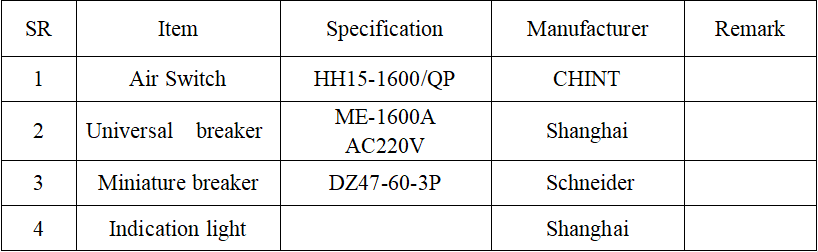

Large diameter pipe seam annealing machine power supply consists of 2 separate SCR induction heating power supply, each power supply has an independent operation control system. The composition of each power supply is as follows:

Switch Cabinet: Provide power cable access, separate control for easy maintenance.

Rectifying & inverter cabinet: The three - phase AC current through SCR to inverter into medium frequency current.

Tank Capacitor Cabinet: provide resonance circuit, including capacitor bank, bus bar, transformer and inductor

Equipped with power switch, convenient single operation, with safety chain under the automatic circuit breaker protection. Main instruments include: power supply voltage display meter, single-phase current display meter, three-color power indicator.

According to the actual production needs of your factory, our company uses the sweep frequency starting annealing machine power supply with advanced level in China in this system. Electrical control board high reliability, all use tile structure for easy maintenance.High power factor.In the peripheral connection has the rich interface to realize the remote control conveniently.

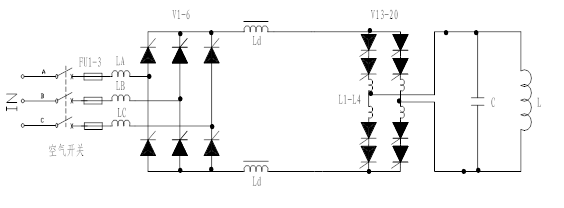

Main circuit principle:

The power supply uses 6 pulse wave rectifier, its circuit principle is as follows:

From the figure, thyristor V1-6 constitutes a three-phase fully controlled 6-pulse full-wave rectifier circuit. Provides DC energy for the inverter section.

The inverter part is composed of thyristor V7-10 and capacitor bank C and inductance coil L. Capacitor bank C and inductance coil L constitute parallel resonance circuit. Compared with series resonance circuit, parallel resonance circuit has better load adaptability and stable and reliable operation.

According to the need of welding seam annealing, chaochang uses the sweep frequency constant power impact-resistant intermediate frequency power source with advanced level in China in this system. Its main features are as follows:

(1) the control system adopts large-scale integrated control, single board structure, to avoid the use of multiple board connector due to poor contact and the operation of the equipment is not reliable phenomenon.

(2) all kinds of signal processing and the implementation of the corresponding action according to the program automatically.

(3) the system instead of various relay control loop to complete the function.

(4) unique swept-frequency start mode, with a 100% start success rate.

(5) the inverter uses the sweeper type zero voltage soft start mode, the start performance is better than the ordinary zero voltage soft start circuit.The general starting process of the sweep mode is as follows: before the inverter circuit starts, firstly, it triggers the inverter thyristor with an excitation signal higher than the resonant frequency of the channel, and controls the frequency of its excitation signal to scan from high to low.When the frequency of its excitation signal drops to near the channel resonant frequency, the if voltage is established.The power supply frequency and L/C resonant frequency are the same through the frequency locking circuit. At this time, the startup is successful.In order to prevent the occasional startup failure of if power supply, our company specially designed automatic repeat startup circuit to ensure 100% startup success rate.

(6) with fast response characteristics of the regulator

According to our company's experience in the actual use of workpiece heating, a unique regulator is designed, whose response time is less than 100mS, which is completely suitable for if power supply to meet the requirements of rapid response in the case of sudden load change.

(7) power constant power output, can ensure high power factor

The specially designed impedance regulator can detect the change of impedance, and feed the change into the circuit for digital operation, automatically adjust the matching of load impedance, and make the power supply reach constant power output.

(8) reliable protection function

The control line is provided with over current, over voltage, incoming line lack of phase, power supply voltage, cooling water pressure is too low and the cooling water temperature is too high protection measures.The sensitivity and reliability of all protection functions are guaranteed.This set of system is water cooling equipment, in order to ensure the safe and reliable operation of the equipment, the temperature of cooling water should be monitored in real time.

(9) advanced phase sequence self-recognition function

The phase sequence self-identification circuit is included in the control system, which eliminates the need to install synchronous transformer in the system and eliminates the work of phase sequence adjustment and synchronization in debugging and maintenance.

(10) the rich external control interface

The device contains internal/external switch, automatic/manual switch and their interface, which can easily realize remote automatic control.And has the temperature outer ring control interface, with infrared thermometer and temperature automatic control system, can easily realize the automatic temperature control.The final heating temperature of the workpiece reaches the expected temperature range through the automatic control system to automatically adjust the output power of the power supply.

(11) Debugging and maintenance is simple and convenient

The setting of most parameters in the control panel is automatically completed by the internal circuit of the control panel, and the user only adjusts the parameters of several potentiometers.So the control board has a strong universality and interchangeability, and debugging and maintenance is very simple and convenient.

(12) The installation of SCR adopts integrated silicon rack, which makes it more convenient to replace SCR.

Welcome to choose our annealing equipment, you can contact us with any questions and we will do our best to help you.

Baoding Chaochang Electromechanical Co., Ltd.

Copyright © Baoding Chaochang Electromechanical Co., Ltd. All Rights Reserved | Sitemap