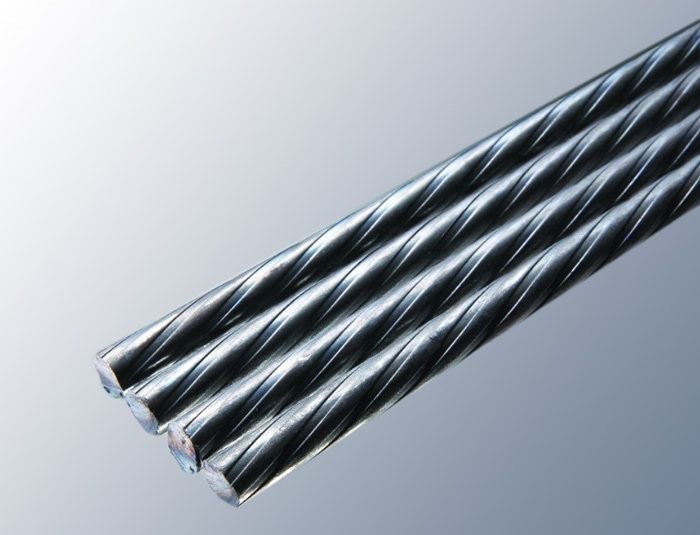

PC(prestressed concrete)bar induction heating production line

| Material | Steel 30MnSi, 35Si etc |

| Diameter of steel | φ 8 ~ 14mm |

| Production speed | φ7.1mm ≤110m/min φ9.0mm ≤100m/min φ10.7mm ≤75m/min φ12.6mm ≤50m/min |

| Max induction quenching temperature | 950℃ |

| Max induction tempering temperature | 580℃ |

| Power Consumption per Ton | φ9.0mm Power consumption per ton ≤370KW·H φ10.7mm Power consumption per ton ≤365KW·H |

Production flow of PC steel bar production line:

Pay-off Stand→Wire-management stand→Mechanical scaling machine→Drawing die→Drawing machine→Straightener→1#Tractor→Preheat Equipment→Heating Power supply →Quenching Power supply + Quenching heat Preservation →Water quenching tank→Tempering Power supply→Water tempering tank→2# tractor →Wire lead slot→Hydraulic reversing shear →1# take-up spool→2# take-up spool

Features of induction heating equipment for PC steel bar:

1. The whole production line is automatic control, including tension control, welding pot automatically shear, wire automatic take-up etc.

2. Installed with temperature tracking system, high precision temperature control and fast heating process.

3. HMI control, convenient to use and do maintenance.

4. Our induction heating equipment has self diagnostic function . With sealed cabinet , it can be applied even under bad environment.

PC(prestressed concrete)bar induction heating production line:

Baoding Chaochang Electromechanical Co., Ltd.

Copyright © Baoding Chaochang Electromechanical Co., Ltd. All Rights Reserved | Sitemap