The whole set of solid state H.F.welder is composed of switch rectifying cabinet,inverter output cabinet, 2-D adjustable bracket, circulation soft water cooling system and central operation cabinet.

Switch rectifying Cabinet

a. The solid state hi frequency welder rectifying cabinet integrate the switch gear cabinet part and rectifier part.

b. Rectifier adopts all three-phase controlled rectification bridge,the pre-stage passive filter make sure the equipment has a bigger power factor but smaller harmonic content.

c. Control circuit use dual-loop regulator of DC voltage and DC current based on single chip microcomputer, which make sure the DC voltage is continuous smooth adjustable from 0 to rated value.

d. Complete protection function leads to the equipment running safely and steadily.

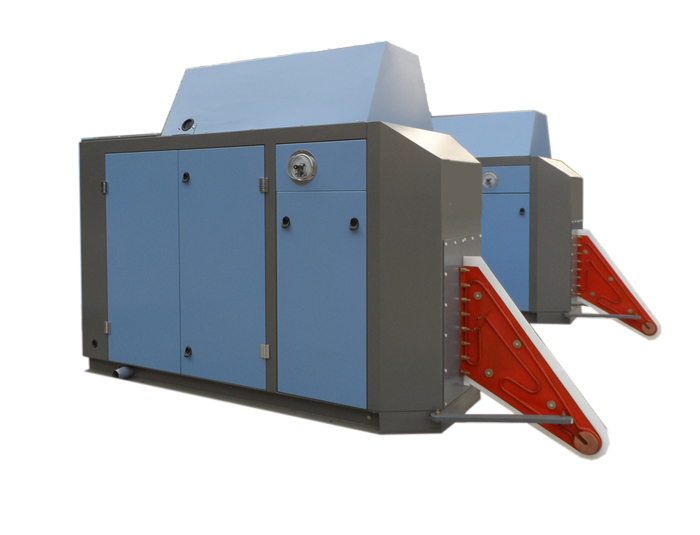

Inverter Output Cabinet

a. The inverter part is consist of MOSFET single phase invert bridge in parallel style.Each bridge’s design power is 120kW/60kW.We adopt building block oe to pile up power,it's very convenient to install and maintain because every single bridge board is designed as drawer structure consisted of slideway.

b. Adopt matching transformer to realize power combination,also adopt sub-resonance and no-welding transformer output mode.

c. Inverter control circuit adopt fixed-angle-control,with a complete protection for lose of lock,over-current and over-voltage to make sure the equipment running safely and steadily.

d. Use sealed box and install water cooling system and air conditioner cooling .

Air -water cooling system or water -water cooling system

The circulation soft water cooling system to cool the exothermic parts of rectifier cabinet and inverter cabinet.

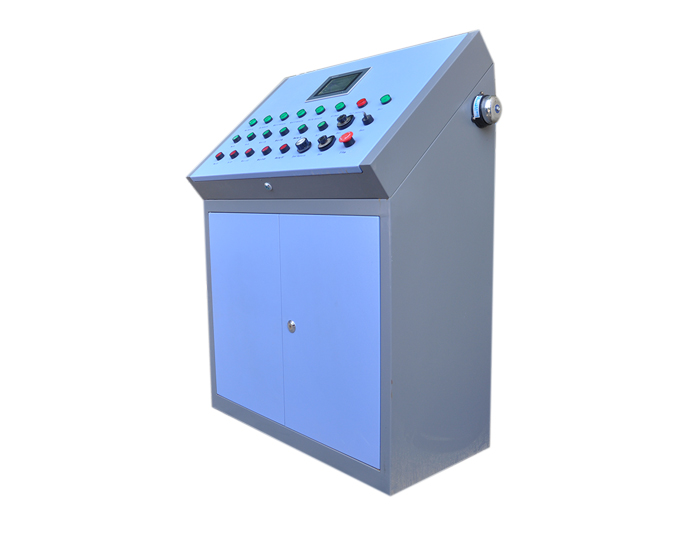

Center Control Console

With PLC and LCD Screen to achieve afar operation of solid state high frequency pipe mills and power regulation.It has speed-power closed-loop control function.

2-D Ajdustable bracket

Baoding Chaochang Electromechanical Co., Ltd.

Copyright © Baoding Chaochang Electromechanical Co., Ltd. All Rights Reserved | Sitemap