Several points that affect the welding quality of the steel pipe when using solid state HF welder:

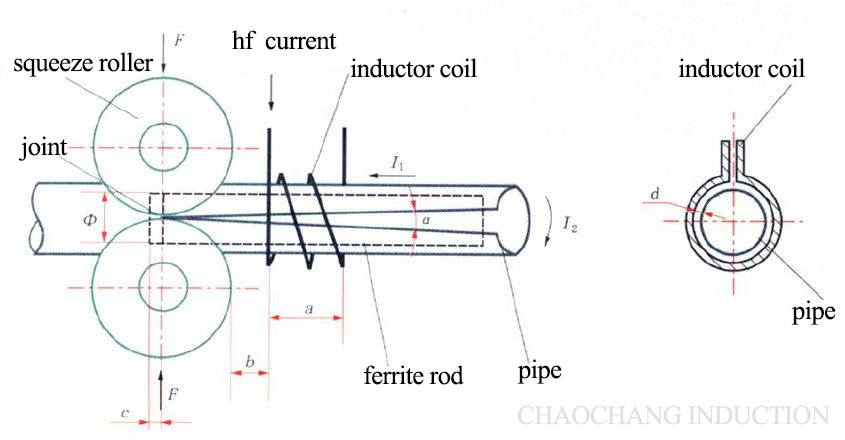

1. Whether the inductor coil is 2 or 3 turns, its width should be controlled at 1-1.2 times the diameter of the welded steel tube.

2.The length of the V-shaped opening (the distance from the induction coil center to the junction point) shall be 1.5 times the diameter of the welded steel pipe. For large diameter thin-walled pipe, this value should be reduced approximately. According to the actual production, sometimes the production unit restricts the realization of this value, then for the pipe diameter below 25mm,this value should be increased properly.

3. For carbon steel, the optimal opening angle a in v-shaped area is 3-5 degree. For stainless steel and non-ferrous metal, in order to prevent false welding and for better welding efficiency, it should be at 5-8 degree.

4. The length of the ferrit rods (Impedance) shall be about 2.5 times the width of the inductor coil. It is very important that the front end of the ferrite rod should exceeds the line 3~4mm (that is, c is 3~4mm) in the center of the squeeze roller, so that the cross -sectional area of the ferrite rod should be 70%~75% of the cross-sectional area of the inner dia of the welded steel pipe, and the ferrite rod should not have crystal cracks.

5. The inner diameter of the induction coil shall be controlled at 15% ~ 20% greater than then out diameter of the welded steel pipe. From the perspective of pure efficiency, as long as the inner diameter of the induction coil can pass through the welded steel pipe, the smaller the gap is, the better it is. However, it is actually impossible to achieve it. The gap must be properly enlarged due to vibration caused by the rapid movement of the mechanical part.

6. The squeeze pressure of the squeeze roller shall be adjusted in place. It should be adjusted according to the unit size, steel pipe diameter, wall thickness and other factors.

7. Quality of steel strip. Whether the edge of the strip is parallel, that is whether the width is same, whether there is a scythe bend,etc. If the burr or irregular body is not completely removed before entering the induction coil after forming, it will reduce the efficiency, and in serious cases, it will cause the ignition between the turns of the inductor coil. Whether the steel strip width meets the requirements or not will affect the speed. Proper width can ensure the quality and speed of welding and could save the raw material.

Baoding Chaochang Electromechanical Co., Ltd.

Copyright © Baoding Chaochang Electromechanical Co., Ltd. All Rights Reserved | Sitemap